PHONE

+91 9811113202, +91 9811193212, +91 7042395754

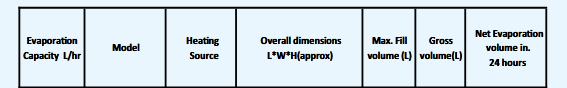

Wide range with different heang sources allow our clients to choose the heang source that is economical & easily available. Our units are plug n play type which makes them easy to install & user friendly and are mainly used by industries having processing of water in their Plant like Coang, Pigment, Metal, Chemical , Laboratories, Food, Pharma industry, Packaging , Washing.

Features

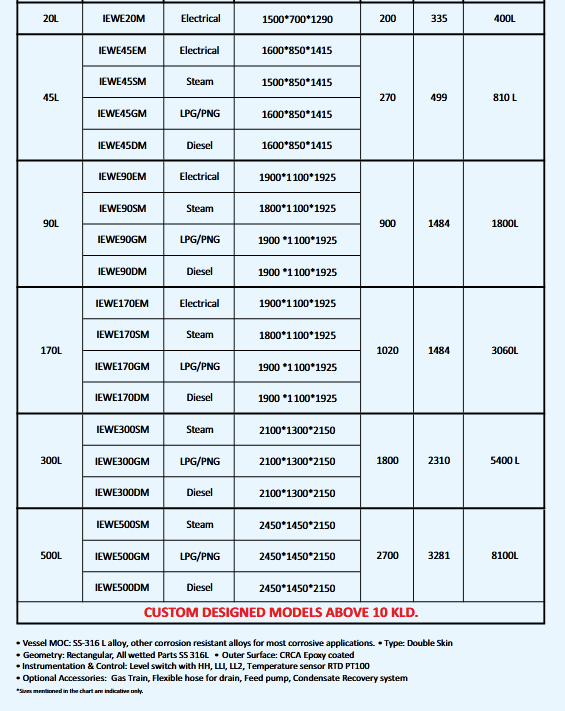

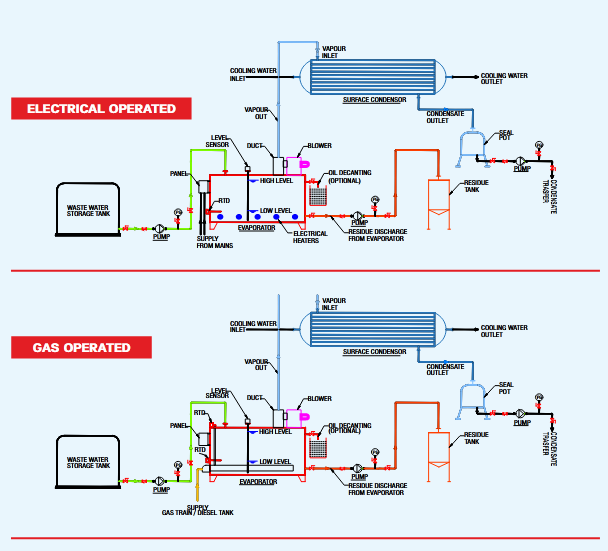

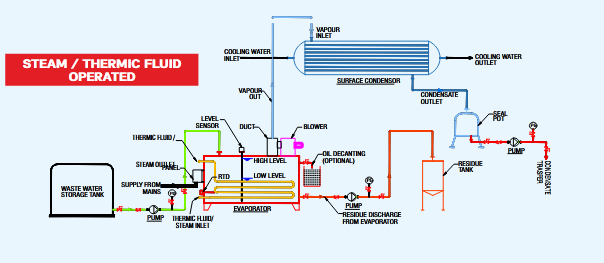

From the main waste water storage tank, add water to the evaporator tank. The liquid level must be at least enough to cover the low level displacement “float” (fied in level indicator pipe). Do not overfill. If the filling is manual through gravity, one should check the level. If it is through pump in auto, it can be interlocked with your pump motor MCC. If foaming occurs adjust the fill level and/or use a defoamer. Foaming is oen mischaracterized as “boiling over”. For oily waste water, free floang oil can be removed through oil decanng pipe.Once water is filled, oil rises to top and forms layer and can be removed through decanng pipe. If the oil is emulsified(suspended homogenously in soluon) oil is removed by auto decanng (chain skimmer) Energise the system Exhaust blower is interlocked with mer and shall start automacally aer 55-60min ( inial heat-up me).Exhaust blower shall expediate the vapour removal. Once the batch is complete, remove the slurry/residues through the drain valve. The residue can be transferred to residue collecon tank through pump. Residue collecon tank is fied with specially designed external pad heaters to evaporate the balance water and the le out( sludge cake) is removed manually by scavenging. Residue can also be sun dried or dried by heat recovery from flue gas of the burner, in case of gas operated or diesel operated system. Condensate recovery is done using surface condenser. Cooling water from the cooling tower is circulated in the surface condenser and the condensate is collected in the seal pot. Further, condensate can be transferred to storage tank through pump

While calculang the operang cost of waste water evaporator, water collected from condensate recovery should also be considered. This will give a clear idea about net opex. Condensate contains a significant amount of sensible heat that can account for about 10% to 30% of the inial heat energy contained in the steam. Feeding the boiler with high-temperature condensate can maximize boiler output because less heat energy is required to turn water into steam. When efficiently recovered and reused, it can even be possible to reduce boiler fuel needs by up to 10 to 20%. Reusing hot condensate can lead to considerable savings in terms of energy and water resources, as well as improve working condions and reduce your plant's carbon footprint. Use of the condensate As heated feedwater, by sending hot condensate back to the boiler's deaerator As pre-heat, for any applicable heang system As hot water, for cleaning equipment or other cleaning applicaon

Efficient wastewater management is a cornerstone of sustainable industrial operations. Integro Engineers provides state-of-the-art solutions through advanced wastewater evaporation systems tailored to meet industry needs. These systems ensure compliance with environmental regulations while optimising resource utilisation, making them indispensable for industries aiming to achieve sustainable operations.

Integro’s wastewater evaporators are built using cutting-edge thermal evaporator technology, ensuring efficient and effective treatment of industrial effluents. These systems separate water from contaminants by heating the waste stream, reducing waste volume and enabling the recovery of reusable water. By employing advanced designs, Integro guarantees minimal energy consumption, seamless integration with zero liquid discharge systems, and reduced operational costs.

Wastewater evaporation systems serve various industries, including pharmaceuticals, textiles, chemicals, and food processing. They are particularly critical for zero-liquid discharge plants, where every drop of water is recovered or treated. Integro’s industrial wastewater evaporators are versatile and can handle high Total Dissolved Solids (TDS) content and complex effluents.

Integro Engineers is a leading manufacturer of wastewater evaporators with a proven track record of delivering efficient and sustainable solutions. Focusing on quality and innovation, Integro’s systems are designed to match the most stringent industry requirements.

A wastewater evaporator uses thermal energy to separate water from contaminants, reducing the volume of waste. It heats the wastewater until it evaporates, leaving behind concentrated solids for easy disposal.

Industrial wastewater evaporators are integral to zero-liquid discharge systems. They help recover reusable water and minimise waste, ensuring compliance with environmental standards.

Industries such as pharmaceuticals, chemicals, textiles, and food processing benefit significantly from wastewater evaporation systems. These industries rely on evaporators for their ability to manage complex effluents effectively.

Integro’s wastewater evaporators are designed to maximise water recovery and reduce waste. They align with sustainability goals while maintaining operational efficiency.

Key factors include the manufacturer’s expertise, the efficiency of their systems, and customisation capabilities. Additionally, energy consumption and after-sales support are crucial considerations. Integro excels in all these areas, making it a trusted choice.