Electrical heat tracing is used to apply heat to :

Integro Provides highest range of heat tracing cables with highest output and highest withstand temperature. The heat tracers are having international approvals by FM, ATEX, IEC Ex, CSA, EAC for use in classified hazardous areas.

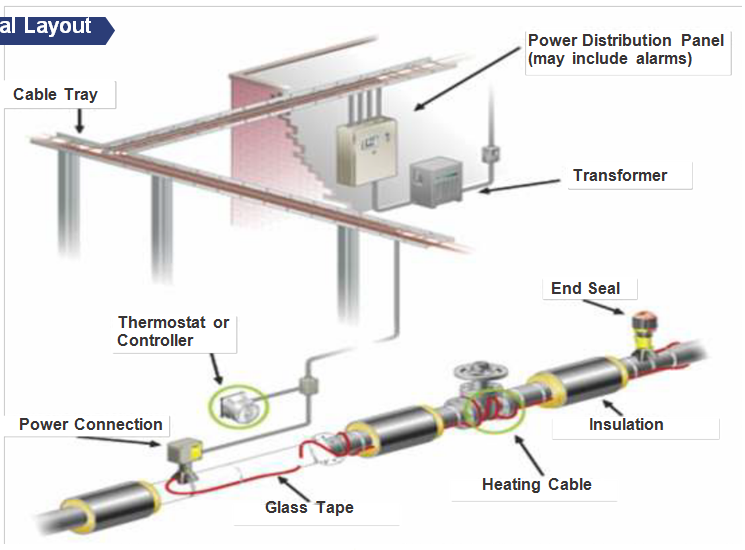

Integro provides junction boxes for terminating heat tracer for power, end, splice TEE and large size cable termination (field junction box). The Junction boxes are suitable for use in safe area, hazardous area and corrosive atmosphere. MOC: LM6, SS304, CRCA, FRP. Protection class IP65

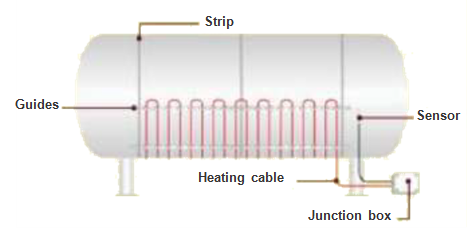

Specially designed “L “ shaped RTD (PT100) and enclosed thermostats , for installation on pipeline and tanks. Suitable for safe and hazardous area installation Mounting stands and installation hardware We provide specially designed mounting stands and hardware for mounting junction boxes, field junction boxes and temperature sensors. We also provide custom designed mounting stands for distribution panels . MOC: MS powder coated or SS304, as per site requirement.

We provide distribution panels for EHT, suitable for safe area, hazardous area , indoor type or outdoor type installation. The panels are custom designed as per the requirement, having incomer and outgoing feeders with safeties and protection devices along with temperature controllers. The panels can be provided with communication facility for communicating with PLC/SCADA and the entire system can be monitored and controlled from control room (Optional)

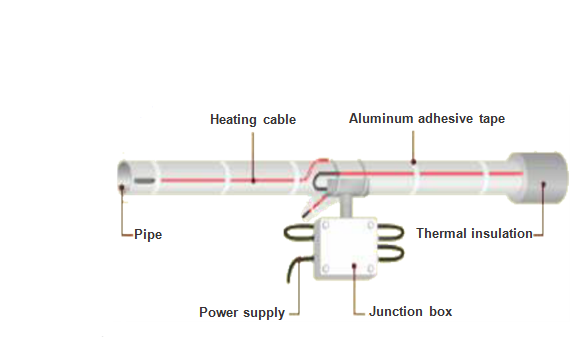

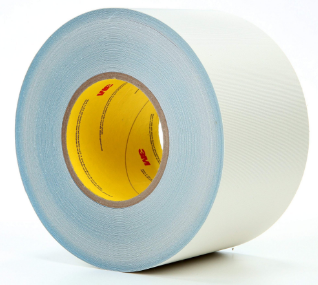

We provide complete set of accessories like adhesive tapes, termination kits, glands and shrouds, power and control cable and warning labels required for EHT system.

Glass Adhesive Tape

Aluminum Adhesive Tape

Cable Shroud

FLP Cable Glands