Type and Range:

Features

Product Quality and Safety.

Maintaining the appropriate temperature during manufacturing processes is essential for ensuring product quality and safety. Circulation heaters provide precise temperature control, minimizing the risk of overheating, underheating, or temperature fluctuations that could adversely affect the final product.

Process Flexibility. The versatility of circulation heaters enables them to be used in various industries. Their ability to accommodate different fluid types, flow rates, and operating conditions makes them adaptable to diverse process requirements.

Process Optimization: Circulation heaters help optimize industrial processes by providing precise and controlled heating. They ensure that fluids reach and maintain the desired temperature, often critical for efficient operations and high-quality output.

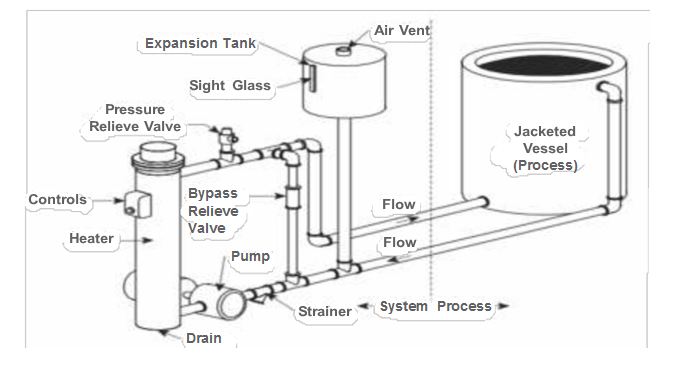

Hot oil and water systems are self-contained heating packages that provide direct or indirect process heating. The systems are pre-engineered to include temperature and power controls, expansion tanks, heat exchanger, pumps, valves, gauges, and all necessary piping. This eliminates component selection and assembly.

Select from oil or water temperature control systems for circulation in a closed-loop process.

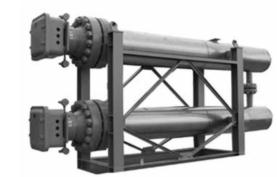

Heat Transfer Systems are used in process heating applications requiring closely controlled process temperatures. Systems are furnished complete with heaters, controls, pumps, valves and necessary plumbing.

• Indirect Heating

• Packaged Systems - Heat Transfer Systems

• Water and Water/Glycol Systems

• Non-Pressurized Hot Oil Heaters

• Pressurized Hot Oil Heaters

• Vaporizers

Heat Transfer Systems are used with:

• Jacketed Vessels and Tanks — containing waxes, paraffin, exotic chemicals including those having exothermic reactions, hot melt adhesives, resins, varnishes, paints, dyestuffs, molasses, vegetable oils and many other chemical or petrochemical products.

• Heated Rolls — for coating paper and paper products, spot carbonizing, vinyl bonding, bonding with hot melt adhesives, calendaring and laminating.

• Heat Exchangers — for corrosive and non-corrosive fluids.

• Platens, Dies and Molds — for laminating wood and plastics, forming of carbon products, epoxy materials and Fiberglass, plastics extrusion, injection molding, molding rubber and plastic materials: vinyl bonding and bonding with hot melt adhesives.

• Pipeline Tracing — of viscous materials such as paints, fuel oils, asphalt and many other chemical and petrochemical products for antifreeze protection and/or maintaining pumping temperatures.

• Industrial Systems — such as snow melting, comfort heating and hot water supply and as standby equipment for industrial and commercial applications in case the supply of other fuels is curtailed.