PHONE

+91 9811113202, +91 9811193212, +91 7042395754

Dried food products such as flour, cereal, dried fruits, pastas and grains are infested by pests which leads to the contaminaon. Such facilies that produce, process handle or sell these products are at risk for infestaon by stored product insects. These pests rapidly aack the dried foods in processing facilies and warehouses, destroying the products.

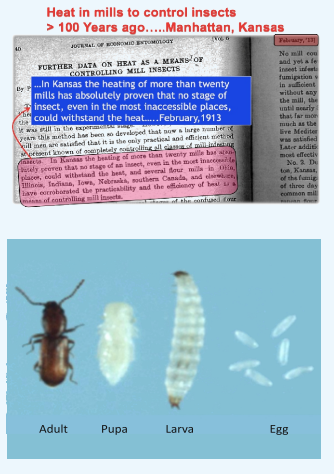

Pest heat treatment is more than a 100 year old technique, proven, tried and tested method of eradicang pests from mills / facilies . The method is known as green heat treatment, since no chemicals are used. In addion to this ,the efficacy of the treatment is very high

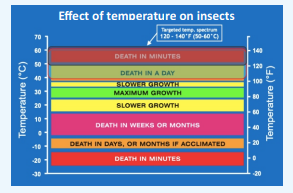

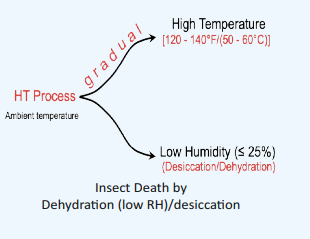

Heat treatment has been recognized as an effecve method to destroy all life stages of insect and pests from eggs to adults. This is safe, effecve and chemical free alternave and is becoming increasingly popular, especially with the phasing out of fumigaon chemicals like methyl bromide and other toxic fumigants which are potenally harmful to people, pets and our environment. Worst yet, chemical pescides are losing their effecveness as pests , are building up resistance to the most commonly used treatment. The process of heat involves safely raising the temperatures in an infested area to the level that is lethal to all insects. Heat penetrates areas where chemicals and fumigants can't reach, providing a more thorough job of prevenng future infestaons. The minimum temperature of 55 deg C is necessary to destroy all life stages of insects in machines, cracks and crevices. The facility is then held at this temperature for 24 hours so that heat the thermal mass of structures to effecvely kill all of the stored product insects.

We manufacture specialized Heat treatment machines suitable for Heat treatment of entire process area or warehouse, mobile system for use at multiple locations

• Custom designed heat treatment of entire process area or warehouse, fixed type.

• Heat treatment of small areas , localized heating, export containers and shipping bins.

Although The Pest Heat Treatment System Is designed to heat treat an enre facility, a cost effecve alternave is a spot or paral Heat Treatment. This method can effecvely control the infestaon in a selected area while the rest of area can operate uninterrupted. Heat treatment of selected areas , spot/localized heang, export containers, bins and silos