PHONE

+91 9811113202, +91 9811193212, +91 7042395754

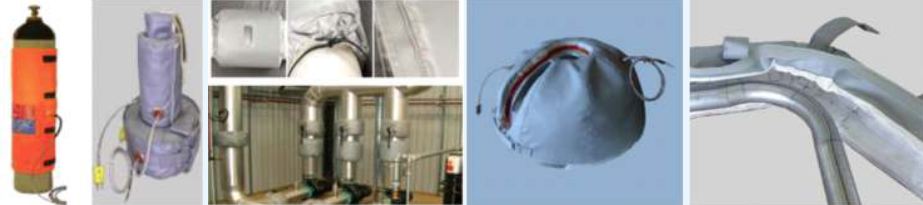

IBC HEATING JACKET FOR 1000L IBC- WRAP AROUND TYPE WITH OPTIONAL TOP INSULATED LID

IBC heating jacket heats up the products inside IBC, reducing the viscosity of products or melting solids so they can be poured. Use of Self-regulating type heating element for heat-up ensures longer life, trouble free operations and eliminates the possibility of hot spots, even if the jacket is in loose contact with the IBC

| Wattage | 2000W |

|---|---|

| Operating voltage | 230V AC, 50HZ (110V volt option also available) |

| MOC | Silicon coated fiberglass mat |

| Heating | Self- regulating type heating cable |

| Control | Analog adjustable Thermostat |

| Fastening | belts with plastic buckles |

| Approximate dimensions | 4405x1010x20mm (thk) with insulation |

| Power ord | 5m |

| Heating cable approval | ATEX/IEC Exd./CCOE |

Features

Integro Engineers offers a wide range of drum heating jackets and IBC heater jackets designed to control precise temperature and prevent heat loss in industrial applications. Whether you need a barrel heater jacket for drums or a flexible drum heating jacket for IBC containers, our high-performance solutions ensure efficient and uniform heating.

High-Performance IBC Heater Jackets for Industrial Applications

Our IBC heater jackets provide controlled heating for intermediate bulk containers (IBCs), ensuring that stored liquids remain at the desired temperature.

Uniform heat distribution for optimal temperature control.

Available in various sizes and wattages to suit different IBCs.

Adjustable thermostats for precise heat management.

IBC insulation jacket options for energy-efficient heating.

Durable and weather-resistant materials for long-term use.

Preventing freezing of liquids in IBCs.

Maintaining the viscosity of chemicals and food products.

Ensuring consistent temperature for pharmaceutical and cosmetic formulations.

Our flexible drum heating jacket solutions extend beyond barrels and IBCs. We also offer heating jackets for pipes, valves, and pumps, ensuring efficient heat retention in industrial processes.

Flexible design for easy installation on irregular surfaces.

Even heat distribution prevents cold spots and thermal loss.

Customisable solutions for various pipe and pump sizes.

These IBC and drum heating jackets help industries maintain operational efficiency by preventing heat loss and ensuring process stability.

Integro’s IBC insulation and barrel heater jackets are designed to minimise heat loss while maintaining energy efficiency.

Insulated layers reduce energy consumption.

Protection against external temperature fluctuations.

Cost-effective solution for industrial temperature control.

Whether you need an IBC heater jacket or an insulated drum heating solution, our advanced designs help industries save energy and improve heating efficiency.

Our drum heating jackets and IBC jackets can be customised to meet specific industry requirements, including:

Food & Beverage: Safe heating for food-grade liquids.

Pharmaceuticals: Precise temperature control for sensitive ingredients.

Chemical Processing: Viscosity control for adhesives, oils, and resins.

Manufacturing & Logistics: Preventing freezing of stored liquids in cold environments.

We provide industry-specific flexible drum heating and IBC insulation jackets that enhance operational efficiency.

High-Quality Materials: Durable construction for long-lasting use.

Efficient Heat Distribution: Prevents overheating and thermal loss.

Custom Options: Tailored solutions for various industrial needs.

Energy-Efficient Designs: Reduced energy costs with insulated options.

Expert Support: Professional consultation and guidance.

Our barrel heater jackets, drum heating jackets, and IBC heater jackets provide reliable temperature control for various applications.

1. What are the primary applications of heating jackets?

Heating jackets maintain temperature in drums, IBCs, pipes, and pumps, preventing heat loss and ensuring process efficiency in food, pharmaceuticals, and chemicals.

2. Are your heating jackets suitable for hazardous environments?

Our drum heating jackets and IBC heater jackets are designed with safety features, including explosion-proof options, for use in hazardous environments.

3. What heating elements are used in your jackets?

Our barrel heater jackets and IBC jackets use high-quality silicone heating elements and insulated layers to ensure even heat distribution and energy efficiency.

4. Can these jackets be used in food and pharmaceutical industries?

Our IBC insulation and drum heating jackets are designed for food-grade and pharmaceutical applications, ensuring compliance with industry standards.

Drum/Canister heating jackets, comprising of Self-

regulating or constant wattage heating element

sandwiched between 2 layers of silicon coated fiber glass

fabric and layer of insulation.

Operating voltage options: 120V / 208 -277V AC,

50-60HZ