PHONE

+91 9811113202, +91 9811193212, +91 7042395754

Circulation heaters, as used for indirect heating, are specialized heating devices that heat fluids flowing through a closed-loop system. They are widely used in various industries requiring precise and efficient heating. The primary purpose of circulation heaters is to maintain the desired fluid temperature during circulation, ensuring optimal process conditions and preventing issues such as viscosity changes crystallization, or freezing.

Type and Range:

Features

Product Quality and Safety. Maintaining the appropriate temperature during manufacturing processes is essential for ensuring product quality and safety. Circulation heaters provide precise temperature control, minimizing the risk of overheating, underheating, or temperature fluctuations that could adversely affect the final product.

Process Flexibility. The versatility of circulation heaters enables them to be used in various industries. Their ability to accommodate different fluid types, flow rates, and operating conditions makes them adaptable to diverse process requirements.

Process Optimization: Circulation heaters help optimize industrial processes by providing precise and controlled heating. They ensure that fluids reach and maintain the desired temperature, often critical for efficient operations and high-quality output.

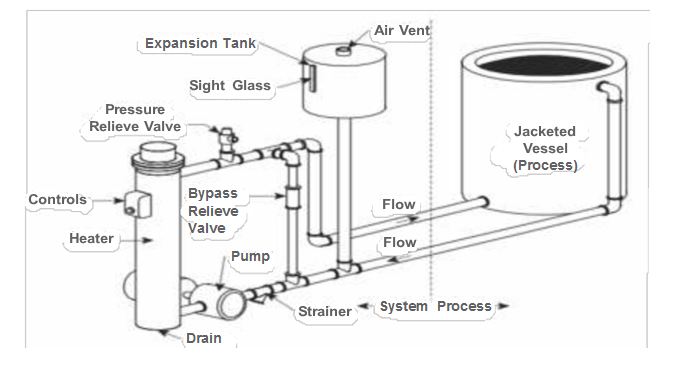

Hot oil and water systems are self-contained heating packages that provide direct or indirect process heating. The systems are pre-engineered to include temperature and power controls, expansion tanks, heat exchanger, pumps, valves, gauges, and all necessary piping. This eliminates component selection and assembly. Select from oil or water temperature control systems for circulation in a closed-loop process.

Heat Transfer Systems are used in process heating applications requiring closely controlled process temperatures. Systems are furnished complete with heaters, controls, pumps, valves and necessary plumbing. • Indirect Heating

• Packaged Systems - Heat Transfer Systems

• Water and Water/Glycol Systems

• Non-Pressurized Hot Oil Heaters

• Pressurized Hot Oil Heaters

• Vaporizers

Heat Transfer Systems are used with:

• Jacketed Vessels and Tanks — containing waxes, paraffin, exotic chemicals including those having exothermic reactions, hot melt adhesives, resins, varnishes, paints, dyestuffs, molasses, vegetable oils and many other chemical or petrochemical products.

• Heated Rolls — for coating paper and paper products, spot carbonizing, vinyl bonding, bonding with hot melt adhesives, calendaring and laminating.

• Heat Exchangers — for corrosive and non-corrosive fluids.

• Platens, Dies and Molds — for laminating wood and plastics, forming of carbon products, epoxy materials and Fiberglass, plastics extrusion, injection molding, molding rubber and plastic materials: vinyl bonding and bonding with hot melt adhesives.

• Pipeline Tracing — of viscous materials such as paints, fuel oils, asphalt and many other chemical and petrochemical products for antifreeze protection and/or maintaining pumping temperatures.

• Industrial Systems — such as snow melting, comfort heating and hot water supply and as standby equipment for industrial and commercial applications in case the supply of other fuels is curtailed.

Integro Engineers specialise in circulation heaters that provide efficient and uniform heating for industrial applications. Whether you need a circulating immersion heater, circulating tank heater, or an inline circulation heater, our solutions ensure optimal temperature control for liquids, gases, and other process fluids. As a trusted manufacturer of circulation heaters, we offer high-performance heating solutions tailored to your industry requirements.

Our industrial circulation heaters are engineered to enhance productivity, minimise energy loss, and maintain consistent heat levels across various processes.

High Thermal Efficiency: Reduces heat loss and enhances energy savings.

Durable Construction: Made from corrosion-resistant materials for long-lasting performance.

Precise Temperature Control: Ensures accurate heating for various industrial applications.

Safety Features: Includes over-temperature protection, insulation, and fail-safe mechanisms.

Customisable Designs: Available in different sizes, wattages, and configurations. Industries can achieve precise temperature control

with our advanced circulating tank heater while improving efficiency.

At Integro Engineers, we understand that industrial processes require customised heating solutions. We design and manufacture custom-built circulation heaters to meet specific operational needs.

Flexible Design Options: Horizontal and vertical mounting configurations.

Material Compatibility: Stainless steel, Incoloy, and other high-performance materials available.

Wide Temperature Range: Suitable for high and low-temperature applications.

PLC & BMS Compatibility: Seamlessly integrates with industrial automation systems.

Whether you need a circulating immersion heater or an inline circulation heater, our team can develop a solution that meets your needs.

Our industrial circulation heaters are designed for demanding applications across multiple industries, ensuring powerful and precise heating solutions.

Oil & Gas: Preheating crude oil, fuel, and lubricants.

Chemical Processing: Maintaining viscosity and preventing solidification.

Food & Beverage: Heating water, oils, and other food-grade liquids.

Pharmaceuticals: Sterilization and temperature control of chemical solutions.

Power Generation: Heating thermal fluids for turbines and generators.

Industries can improve process control and thermal efficiency with our cutting-edge circulation heaters.

Integro Engineers prioritises quality, innovation, and customer satisfaction as a leading circulation heater manufacturer. Our heaters undergo rigorous testing to ensure optimal performance and longevity.

Expert Engineering: Designed with industry-leading technology.

Reliable Performance: Ensures consistent heating with minimal maintenance.

Energy-Efficient Designs: Reduces operational costs while maximising output.

Comprehensive Support: From finalising products to after-sales service.

Whether you need a circulating tank heater or an inline circulation heater, we provide top-tier solutions backed by industry expertise.

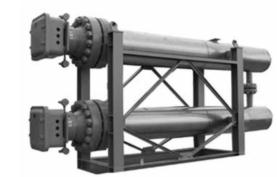

Integro’s inline circulation heaters are perfect for continuous-flow heating applications. They ensure efficient heat transfer while maintaining process fluid integrity.

Compact & Space-Saving Design

High-Watt Density for Faster Heating

Suitable for High-Pressure Applications

Custom Flow Rates & Heating Capacities Available

Our industrial circulation heaters offer a reliable and effective solution for businesses seeking to improve their heating efficiency.

1. What industries benefit from circulation heaters?

Circulating tanks and industrial circulation heaters, which provide precise and efficient heating, benefit industries such as oil and gas, food processing, pharmaceuticals, chemical manufacturing, and power generation.

2. How do I choose the right circulation heater for my application?

When selecting a circulating immersion heater or an inline circulation heater, factors like the required temperature range for the fluid type, pressure conditions, and heating capacity should be considered. Our team can help you find the best solution.

3. Are your circulation heaters compatible with PLC and BMS systems?

Our circulation heaters integrate seamlessly with PLC (Programmable Logic Controllers) and BMS (Building Management Systems) for automated process control.

4. Do you provide custom-built circulation heaters?

As a specialised circulation heaters manufacturer, we design and manufacture custom-built circulation heaters tailored to specific industrial applications.

5. What is the typical lifespan of an industrial circulation heater?

Thanks to the durable construction and high-quality components, our industrial circulation heaters can last several years with proper maintenance.

.