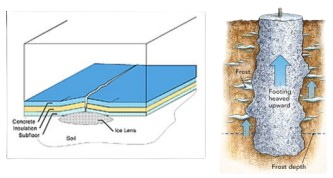

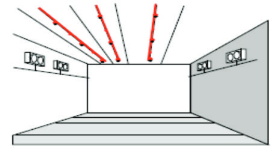

Design basis/Heating system confirming to IEEE standard 515.1-1995 Design parameters required: Cold Room size Insulation Type and thickness, concrete thickness Cold room Temperature: Temperature to be maintained at substra for frost heave protection = 5 degC System details: Self- regulating type heating cable, cut to length, having stranded copper bus wire for caring current, semi conductive self- limiting matrix, thermoplastic elastomer insulation, continuous conductive covering of tinned copper braid and thermoplastic outer jacket. Suitable for the minimum installation temperature of (-) 40 degC. Suitable for installation in both metallic and non -metallic conduits. Operating voltage range: 220-277V AC Junction boxes: Weatherproof IP65, for power and end terminations with double compression glands and mounting kits. Termination Kits for power and end seal termination. Control box comprising of digital temperature controller and ELMCB/RCBO of suitable rating. Sensor (RTD, PT100) for temperature sensing Installation method (method 1-heating mats) Heating Cables pre-fitted on flexible mats as per the design requirement, are laid on the cold room sub floor as per the drawing provided with the system. Junction boxes are fitted on the

- Frost Heave protection (Underfloor heating)

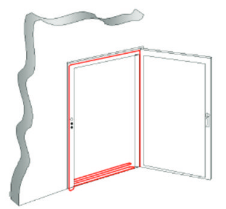

- Freezer door heating cable

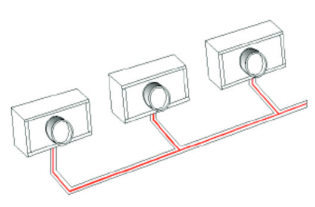

- Freezer drain Lines heating cable

- Fan cowling heating cable

- Viewing glass heating cable

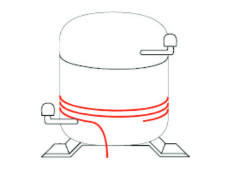

- Compressor body heating cable

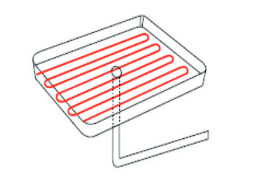

- Dip tray heating cable / heated dip tray

- Safety vents heating cable

- Fire protection Sprinklers heating cable

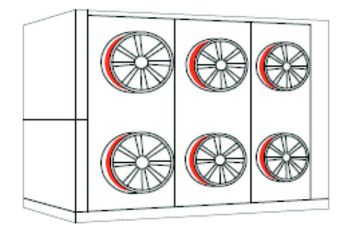

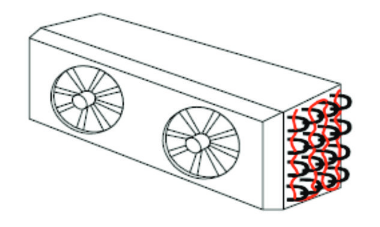

- Evaporator Bends heating cable

We offer Heating solution for walls/stand and control system is fitted at nearby convenient location. Installation method (method 2) Heating cable shall be installed in a minimum 3/4" conduit within the base layer of the substrate, approximately 50mm below the insulation. Junction boxes to be located along wall or any other suitable locations as per the design requirement. Junction boxes must be accessible for wiring and other operations without removing concrete or building part. Location of junction box must be at least 50mm above finished floor. Conduit spacing: centre to centre distance between two conduits shall be 1.2m Testing: Heating cable shall be tested with the minimum 1,000 Vdc megger. This test should be performed a minimum of three times. The minimum acceptable level for the megger readings is 20 megohms, regardless of the circuit length